Written by Esther Lansdaal, Senior Application Specialist – Corbion

The chemicals and synthetic ingredients that were once relied on to give creams and lotions their smooth, creamy and luxurious textures are now being shunned by consumers in preference for the environmental and beauty benefits of natural and organic ingredients. But what does natural really mean when it comes to personal care products? And how can formulators harness the power of natural ingredients without compromising performance?

Sustainability versus performance

Whilst popular with consumers, there is a common misconception that natural ingredients equate to lower performance formulations that require additional ingredients to achieve the desired aesthetic and performance attributes. However, with the move towards clean-label, formulators are looking to use less ingredients in their products and therefore require natural ingredients that can deliver the same benefits as the synthetic alternatives.

In answer to this formulation challenge, a new generation of safer and milder emulsifiers and surfactants has emerged that deliver the performance properties of traditional formulations, while allowing brands to offer consumers enhanced sustainability credentials for their products.

Introducing LGNs

Emulsions are widely used in cosmetics and skincare for their stability, performance and aesthetic attributes. This includes lameller gel network emulsions (LGNs) – formed when suitable LGN emulsifiers are chosen. In doing so, formulators are able to achieve enhanced skincare attributes through the effective delivery of active ingredients. Here, we discuss the benefits of lamellar gel network emulsions further and the benefits they deliver when it comes to robust, safe and sustainable creams, gels and lotions.

The lowdown on LGN emulsions

Whether for hair conditioners, skin or sun care products, selecting the right LGN-appropriate emulsifier(s) that can be used in LGNs, these emulsions can provide a range of unique performance and aesthetic benefits.

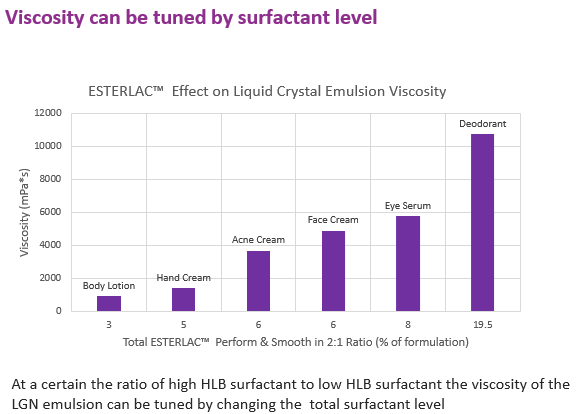

In general, the purpose of the low HLB surfactant (e.g. glycerol monostearates and saturated fatty acids) is to create structure and thicken the formulation. The high HLB surfactant (e.g. actyl lactylates and lecithin) swells the low HLB surfactant to form a liquid crystalline lamellar gel, which together form a highly stable lamellar bilayer. In addition, at a certain ratio of high HLB surfactant to low HLB surfactant the viscosity of the LGN emulsion can be tuned by changing the total surfactant level. This offers formulators greater flexibility when it comes to developing creams, lotions and serums, which all require different viscosity levels.

Now though, there is a unique ingredient – ESTERLAC™ Perform – that can form an LGN base formula without the use of other emulsifiers. This allows the formulator to make a base by heating water to 80°C, adding the emulsifier until it is until molten and uniform and then, after cooling, adding a preservative. This base can be stored and used at a later date by simply adding any oil and other ingredients while it is still cold.

Graph 1: the impact on viscosity of using ESTERLAC surfactants

LGNs offer formulators a simpler solution compared to traditional types of emulsifiers. They require processing in a different way to achieve excellent emulsions, but guidelines are available to ensure the correct procedures are followed. Water is heated to 80°C before adding the emulsifier(s) and waxes. These components are then stirred until melted in the water phase, before adding the cold oil phase while the aqueous phase is warm or cooled. A low level of polymer is then added for high temperature stability. It is important is not to heat the oil phase and ensure stirring is gentle to ensure low shear. Intensive or excessive mixing would break the lamellar gel network.

Changing emulsifier to change aesthetics

LGN emulsions play a key role in determining the aesthetics of a formulation. In a study by Wiechers et. al., emulsions were found to provide 74% of the aesthetic quality of a product and nearly 100% of its appearance, pick-up and rub-out characteristics. Formulators will therefore often change the emollient to alter the aesthetics of a product. However, the emollient is an expensive component of a product and studies have shown that superior results can be achieved by changing the emulsifier. By changing the emulsifier system into a lamellar gel network with suitable emulsifiers, it is possible to form different textured materials – from light moisturizing lotions and creams to buttery emulsions. This offers manufacturers the flexibility to create a wider range of products with fewer, cost-effective ingredients.

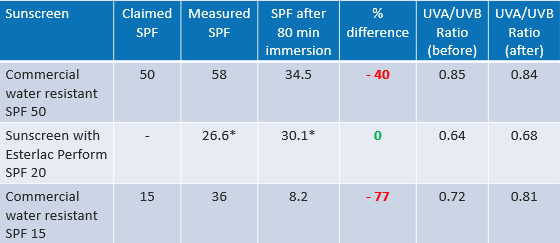

Enhancing the water resistance of sun care products

An additional advantage of LGN emulsions, in relation to sun care applications, is improved water resistance. Generally, o/w emulsions are more widely used in personal care applications. For water-resistant sunscreen, however, w/o emulsions are the preferred format. Water-resistant by design, w/o emulsions provide better efficacy for the same concentration of sunscreen actives. However, they are notoriously difficult to formulate. Lamellar gel systems provide enhanced occlusivity and improved water resistance. A study, comparing sunscreen formulated from LGN emulsions against commercial sunscreens, showed superior water resistance in the former. After 80 minutes of immersion, the SPF of the LGN formulation remained constant, whereas the measured SPF of the commercially-available, water-resistant SPF15 sun cream had decreased by 77%.

* SD: +/- 4

Harnessing the natural beauty benefits of actyl lactylates

Corbion’s ESTERLAC™ portfolio of emulsifiers, which is based on actyl lactylates (high HLB surfactants) and glycerol mono stearates (low HLB surfactants), can be used by formulators to develop highly stable lamellar-based gel network emulsions for a range of personal care applications.

Forming part of the skin’s natural moisturizing factor, actyl lactylates are prepared from naturally occurring raw materials; lactic acid and fatty acids. The lactic acid used in the ESTERLAC™ range is derived from sources such as corn, sugar cane and tapioca via fermentation, while fatty acids are produced industrially by the hydrolysis of triglycerides, such as palm, sunflower and coconut oil.[1] The lactylates are then manufactured through a reaction between lactic acid, fatty acid and hydroxide, resulting in a readily biodegradable product and removing the need for polymer compounds which have fallen out of favor with today’s discerning consumer.[2] The ESTERLAC™ range therefore enables formulators to switch from oil-based synthetic emulsifiers to a more natural alternative.

One of the biggest benefits of lactylates is their low toxicity and skin irritation profiles. The safety profile of the entire ESTERLAC™ range has been rated 1 – the lowest hazard rating – by the Consumer Safety Group Environmental Working Group. In addition, it is manufactured in US FDA-registered facilities with Good Manufacturing Practice (GMP) in place, allowing them to be classified as food grade suitable quality. This provides formulators with additional confidence in the safety profile of these high-performance emulsions.

Formulating LGNs with ESTERLAC™

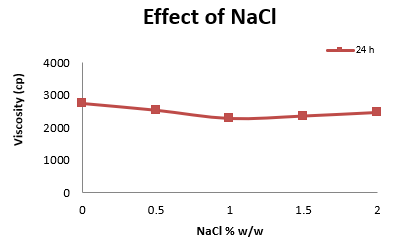

LGNs formulated with the ESTERLAC™ product range perform multiple functions; from moisturizing and conditioning, to boosting foam and viscosity and enhancing skin penetration. Tests have shown that ESTERLAC™ LGNs used in moisturizing creams are very stable, even at high temperatures, and the pH of the LGN also remains consistent over prolonged periods In addition, LGN emulsions have been shown to be tolerant to electrolytes, with high doses of NaCI and sodium lactate having no effect on viscosity in tests (see graph 2). The addition of solvents has also been shown to have no effect on the viscosity of LGNs formulated with ESTERLAC™.

Graph 2: the addition of sodium lactate has almost no impact on viscosity in LGN emulsions

Simpler formulations, superior performance

ESTERLAC™ enables formulators to develop a wide range of personal care products using less ingredients while still achieving the same levels of performance. This robust chassis can be easily incorporated into existing formulations or tailored for specific applications. To achieve the required levels of foaming for select products, some natural surfactants require additional ingredients to be added to the formulation. Meanwhile, ESTERLAC™ does not require any additional ingredients, addressing the global trend for simple formulations with fewer ingredients.

With the increasing demand for more sustainable personal care products, formulators are having to re-think the development process. ESTERLAC™ is not a drop-in replacement for synthetic emulsifiers, but is designed to support brands and formulators in creating new formulations that meet consumer demand for natural products that are safe, sustainable and kinder to the skin.

The simpler way to a greener future

In the journey towards cleaner, greener and more sustainable products, it is important to remember that just because an ingredient is marketed as natural, doesn’t necessarily mean it is safe. There is currently no clear definition of what natural means for personal care applications and although efforts are being made to quantify its meaning, many current claims are often marketing-led rather than science-backed. Collaboration across the supply chain is required to establish a clear proposition as to the meaning of naturalness within cosmetic and personal care products. ESTERLAC™ LGNs offer performance benefits that meet, and in some cases exceed, those of synthetic formulations while harnessing the natural benefits of lactylates for safer and more sustainable personal care products.

To rediscover the benefits of natural surfactant and emulsifier ingredients and find out how you could achieve superior performance with simpler formulations, please click here.

- Retrieved on May 1st 2018 from: www.fediol.be

- Carbon dioxide evolution text by Corbion Caravan Ingredients (2007)