Written by Kelly Dobos

Colors in Cosmetics – Color Measurement and The Importance of Pigment Dispersion

The incorporation of color in cosmetic and personal care products is part art and part science. What seems like a simple and fun exercise in pigment blending is reliant on a complex set of decisions. Factors such as the regulatory environment, cost, and stability as well as physical and chemical properties of each colorant all play an essential role in determining success in product development. Dispersion is one most important processes in utilizing pigments to create color cosmetics.

Color Theory

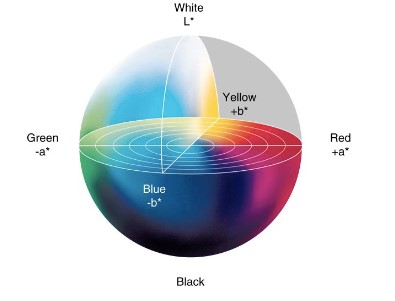

To begin a discussion on color theory, we can start with the work of Alfred Henry Munsell in the early 1900s. Munsell, an artist and professor at the Massachusetts Normal Art School (known today as the Massachusetts College of Arts and Design), was perplexed that there was no easy way for artists to communicate color in a systematic and consistent manner similar to the way in which music was transcribed. The relationships between these three attributes can be portrayed in a three-dimensional space as a color sphere. Sophisticated spectrophotometers can be used to precisely measure these attributes using the CIE-Lab (pronounced see lab) color space, which was created by the International Commission on Illumination (CIE) in 1931. CIE-Lab measurements are commonly used to control quality of cosmetic pigments and finished goods.

Color Perception

There are three factors involved in color perception – a light source, the interaction of light with an object and the response of a standard observer. Our light source is the visible portion of the electromagnetic spectrum. The standard observer is a typically the human eye or a spectrophotometer.

Attributes of Color

There are three main attributes used to describe color.

- Hue: Commonly referred to as shade or color. Descriptors for hue are simply colors like red, green, yellow and blue. However, there are many degrees of differentiation in color. For example, red can be yellow shade or blue shade.

- Brightness: Or value, is a measure of how light or dark the color is.

- Intensity: Measures the colors saturation, how weak or strong it is. This attribute is also referred to as chroma.

The CIE-Lab color difference equation calculates coordinates to locate a point in the in the three-dimensional sphere model. The coordinates are for the L*, a* and b* axis. L* is a measure of lightness to darkness. a* is the red to green axis and b* is yellow to blue. Color differences are calculated from these coordinates and represent the distance between the target and trial along each axis.

Dispersion

Let’s get a few definitions out of the way:

- Classical Pigments are insoluble in the medium in which they are used primarily used in decorative color cosmetics.

- Dyes are soluble in the medium in which they are used. They are primarily used in personal care products.

- Effect pigments are pearls, glitters and metallic materials used to create different finishes, from satin-like looks to sparkle, in cosmetics and personal care products.

The focus of this post is classical pigments, and perhaps I’ll get to tackle the other two types in additional posts.

Classical cosmetic pigments are made in large batches and there are unavoidable, slight variations in shade or other qualities from batch to batch. The pigments are typically supplied as dry powders where primary particles exist in various states of aggregation and agglomeration that amplify the variation in color properties when evaluated as dry powders.

These pigments cannot be simply stirred in, dispersion is extremely important in getting the full value out of a pigment in formulation and in evaluating pigments for quality control. These pigments must be fully extended or dispersed in a vehicle to get as close as possible to primary particle size to see the full development of color.

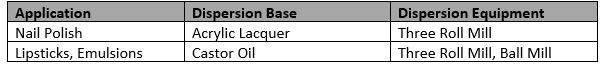

Dispersion is the process of wetting, separating and distributing pigment particles in a medium. Dispersion requires intense energy input through high sheering in liquids or pulverization in powders. See table below for some specific examples of dispersion vehicles and equipment.

A particle size of 3-5 µm is necessary for optimum color development. Fineness of grind can be easily measured with an instrument called a Hegman Gauge. The ability of pigment to absorb light increases with decreased particle size and increased surface area. One note of caution, pigments can be over-milled resulting in lower color development.

Oil Absorption

Another important factor in pigment dispersion is the oil absorption capacity of individual pigments. Based on both chemical structure and the type and amount of substrate present in pigments, they will exhibit a wide range of oil absorptive powers. For this reason, the pigment to oil ratio for dispersion varies and it is easiest to work with single pigment dispersions. This property is significant in the formulation of lipsticks as the oil absorption of a pigment has a major impact on the hardness of the stick. It also impacts the rheology of an emulsion system. Oil absorption is an important factor in controlling the consistency across a line of colors in a lipstick range or liquid foundations.